Temperature of Media:Medium Temperature

Pressure:Medium Pressure

Power:Hydraulic

Media:Water

Port Size:DN63

Structure:ball or spring

Standard or Nonstandard:Standard

Name:Pvc Foot Valve

Color:Grey

Type:Spring+Ball

Size:1/2"-3"

Medium:water

Standard:ANSI BS DIN JIS

Working pressure:8KG

Surface:plastic

Connection:Female Thread

Seal Material:NBR EPDM VITON

The bottom valve can withstand temperature -10 degrees 65 degrees, can resist general acidic, alkaline, oxidizing solutions, but will be corroded by aromatics, hydrocarbons, ketones, esters and other chemicals

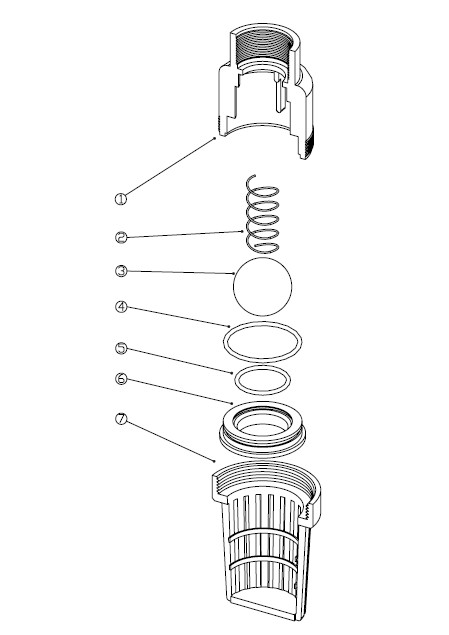

parameter

|

ITEM |

COMPONENT |

MMATERIAL |

QUANTITY |

|

1 |

BODY |

U-PVC |

1 |

|

2 |

SPRING |

STAINLESS STEEL |

1 |

|

3 |

BALL |

U-PVC |

1 |

|

4 |

O-RING |

EPDM·NBR·FPM |

1 |

|

5 |

O-RING |

EPDM·NBR·FPM |

1 |

|

6 |

SEAL CARRIER |

U-PVC |

1 |

|

7 |

BONNET |

U-PVC |

1 |

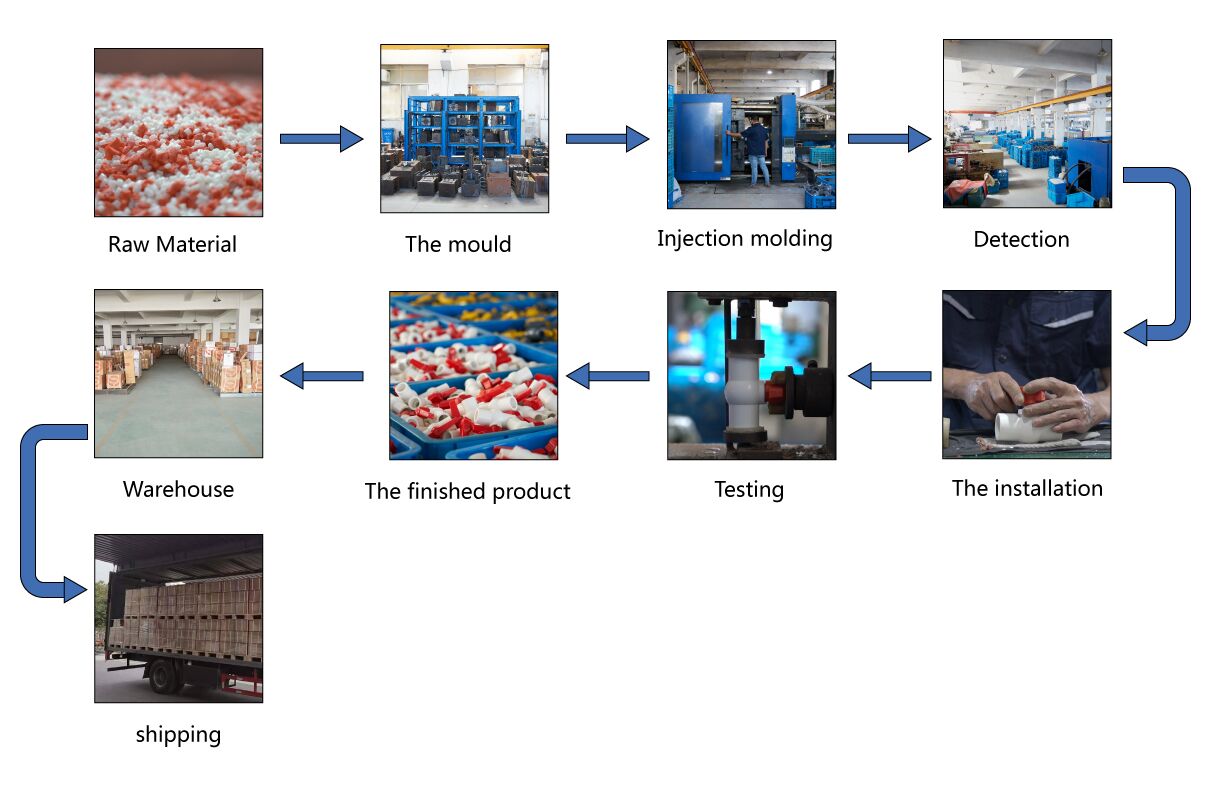

process

Raw Material, The mould, Injection molding, Detection, The installation, Testing, The finished product, Warehouse, shipping.

features

According to the material, the bottom valve can be divided into plastic bottom valve and metal bottom valve. It can also be divided into ordinary bottom valve and bottom valve with backwash water flow. The bottom valve is mainly used in water pumps and other mechanical equipment that handles slurry. Usually the bottom valve is installed at the bottom of the pump's underwater suction pipe to prevent the slurry from returning. The quality of the bottom valve of domestic brands is generally poor. If the seal is not tight, there is water leakage. Problems, etc., such a system is difficult to realize automatic control, and it is very troublesome to fill the straw with water every time. This is Fengquan quality, designated production of chemical equipment. The main purpose of the acid and alkali resistant bottom valve: the bottom valve is light in weight and easy to install. The connection methods are: bonding type, and the product structure is: floating ball type. It can be used with various centrifugal pumps and self-priming pumps. The product has a novel structure and superior sealing performance. It can resist acid, alkali and corrosion. It has a long service life. It is widely used in chemical industry, chemical fiber, chlor-alkali, electric power, pharmaceuticals, Dyestuffs, smelting, food, sewage treatment, mariculture, and other industries. Acid and alkali resistant bottom valve structure The bottom valve is composed of valve body, valve cover, valve disc, sealing ring and gasket and other parts. The valve disc of the bottom valve has a hemispherical type. of. After the bottom valve is connected to the pipeline, the liquid medium enters the valve body from the direction of the valve cover, and the pressure of the liquid acts on the valve disc, so that the valve disc is opened to allow the medium to flow through. When the medium pressure in the valve body changes or disappears, the valve disc Turn off to prevent the media from flowing back. The bottom valve is equipped with multiple water inlets on the valve cover and equipped with a screen to reduce the inflow of debris and reduce the probability of clogging of the bottom valve. Although the bottom valve is equipped with an anti-clogging screen, the bottom valve is generally suitable for cleaning media, and the bottom valve is not suitable for media with excessive viscosity and particles.